Ngwaahịa

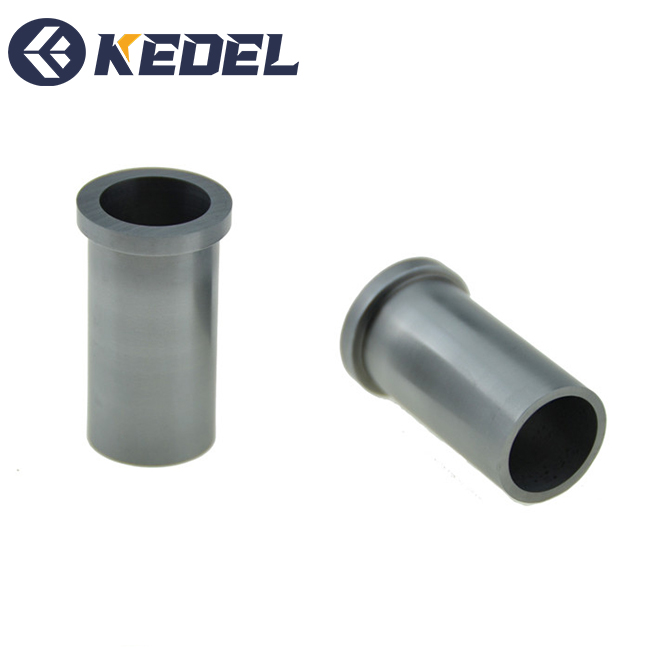

Mgbochi corrosion Tungsten Carbide siri ike YG1C stringed Drill Bushings

Okwu Mmalite ngwaahịa

Tungsten carbide bushing mebere site na akụrụngwa tungsten carbide na-amaghị nwoke.Ọ na-egosi ike isi ike dị elu na ike mgbada.Nke ahụ nwere arụmọrụ dị elu na iguzogide abrasion na corrosion, nke a na-ejikarị eme ihe n'ọtụtụ ụlọ ọrụ

Maka ojiji ya n'ọtụtụ ebe.A na-ejikarị osisi Tungsten carbide mee ihe n'ụzọ ziri ezi, yana n'ihi njedebe ya zuru oke, nha ziri ezi, ịdịte aka na nguzogide corrosion.Ndị ahịa na-enwe ekele nke ukwuu n'ahịa ụlọ na n'ụgbọ mmiri.

Na mgbakwunye, dị iche na mpaghara ngwa ngwa dị iche iche.Enwere ọtụtụ ụdị osisi tungsten carbide.Ọtụtụ n'ime nkọwapụta bụ ahaziri ha niile.Ngwá ọrụ Kedel akwadola site na ihe ọmụma ụlọ ọrụ bara ụba na ahụmịhe mmepụta nke ahịhịa Tungsten carbide dị iche iche.Nke a nwere ike imepụta ihe dị iche iche nke Tungsten carbide bushing dabere na nhazi a kapịrị ọnụ.

Njirimara ngwaahịa

1. Jiri 100% tungsten carbide akụrụngwa

2. Njirimara kemịkalụ kwụsiri ike

3. Ọmarịcha arụmọrụ na ezigbo iyi / corrosion eguzogide

4. HIP sintering, ezigbo compactness

5. oghere, elu machining ziri ezi / nkenke

6. OEM ahaziri nha dị

7. Ụlọ ọrụ na-enye

8. Nyocha ngwaahịa siri ike

Nkọwa nkọwa

Tebụl ihe

| Ọkwa | ISO | Nkọwapụta | Ngwa nke tungsten carbide | ||

| Njupụta | TRS | Isi ike | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Tozuru oke maka iji igwe nkedo oyi, ihe nkedo alloy, igwe nrụgharị na nchara alloy.Tozuru oke maka nhazi igwe nkedo nkịtị. |

| YG06 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Kwesịrị ekwesị maka ịmecha machining na ọkara-mechara maka nkedo ígwè, ígwè na-abụghị ígwè, alloy na unalloyed ihe.Tozuru oke maka ịse waya maka igwe na igwe anaghị agba nchara, igwe eletrik maka ojiji geology na igwe igwe wdg. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ndị ruru eru maka ịrụ ọrụ siri ike nke ígwè nkedo, ígwè na-abụghị ígwè, ihe ndị na-abụghị ígwè, ịbịaru ígwè, ígwè na-adịghị emepụta ihe na ọkpọkọ, ihe dị iche iche maka iji geology mee ihe, ngwá ọrụ maka imepụta igwe na iyi akụkụ. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Tozuru oke maka ịrụ ọrụ siri ike dị ala, igwe igwe titanium alloy na alloy refractory, ọkachasị maka ngwa mbelata na prick silk. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ndị ruru eru maka ịkpụzi ihe ndị ahụ maka egwu nkume dị arọ: ibe n'ibe ndị a na-apụ apụ a na-eji eme ihe maka igwu mmiri miri emi, rock drill trolley wdg. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Tozuru oke maka mkpọpu okwute siri ike, ogwe nchara nwere oke mkpakọ dị elu, ịse ọkpọkọ, ngwa ịkụ ọkpọ, isi kabinet nke ntụ ntụ metallurgy akpaaka wdg. |

| YG20 | 13.4-14.8 | 2480 | ≥83.5 | Tozuru oke maka ime ọnwụ na mmetụta dị ala dị ka akụkụ ntụmadị, shells batrị, obere skru caps wdg. | |

| YG25 | 13.4-14.8 | 2480 | ≥82.5 | Tozuru oke maka imepụta isi oyi, stampụ oyi na ịpị oyi na-eji maka imepụta akụkụ ọkọlọtọ, bearings wdg. | |