Ngwaahịa

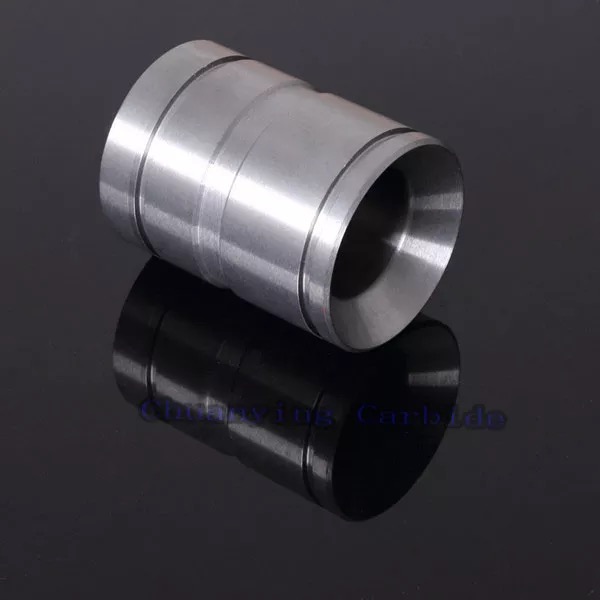

Cimented Tungsten Carbide Bushing Shaft Sleeve Bushing Bearing

Nkọwa ngwaahịa

Cimented carbide polished bushigns bearings bụ ngwaahịa ahaziri nke ụlọ ọrụ anyị maka ndị ahịa. Ọ nwere njirimara nke nguzogide dị elu, ike siri ike na nguzogide corrosion siri ike. Ọ nwere ike ịmepụta liners nke nha dị iche iche ma nye ndị ahịa ikike mmepụta ihe pụrụ iche na nke pụrụ iche.

Ngwa Kedel Carbide na-arụpụta Tungsten Carbide kachasị mma, seramiiki na akụkụ igwe eji arụ ọrụ, ihe MWD na akụrụngwa pụrụ iche maka ngwa na-emebi emebi na abrasive maka ụlọ ọrụ mmanụ & gas.

Anyị na-arụpụta ọtụtụ akụkụ dị ka eruba akara components, bushings, oche, ọnụ ụzọ ámá na ị ga na carbide igbu ibe n'ibe, ported eruba cages na akpali bearings.

Ọtụtụ ụlọ ọrụ mmanụ na gas na-adabere na Ngwa Kedel Carbide iji rụpụta mma, ihe njikwa mmiri tungsten carbide na-adịte aka. Aha anyị n'ichepụta ụdị ejiji na ihe na-achịkwa mmiri na-esi na ahụmịhe anyị na ụlọ ọrụ, akara akara tungsten carbide dị elu na ntinye aka na ndị ahịa anyị.

Atụmatụ anyị

1. Lekwasị anya na mmepụta nke ụlọ ọrụ carbide cimented maka ihe karịrị afọ 15;

2. Ihe ndị dị iche iche nke ụdị dị iche iche zuru oke, nke nwere ike izute ọrụ arụmọrụ nke ọdịda;

3. Ike nhazi siri ike, ihe karịrị 50 CNC igwe ngwá ọrụ, ihe karịrị 20 peripheral grinders na ihe karịrị 20 eluigwe na ala nhazi grinders;

4. Mmepụta ahaziri maka ndị ahịa, OEM na ODM;

5. Ọgaranya ahụmahụ ọrụ ndị ahịa mba ọzọ, na-ejere ndị ahịa ozi n'ihe karịrị mba 50 gburugburu ụwa.

More Tungsten Carbide Bushings Bearing Bush

Tebụl arụmọrụ ihe

| Ọkwa Cobalt Binder | ||||

| Ọkwa | Ihe nchikota (Wt%) | Njupụta (g/cm3) | Isi ike (HRA) | TRS (>=N/mm²) |

| YG6 | 6 | 14.8 | 90 | 1520 |

| YG6X | 6 | 14.9 | 91 | 1450 |

| YG6A | 6 | 14.9 | 92 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88 | 1810 |

| YG15 | 15 | 14 | 87 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |

| YG25 | 25 | 12.1 | 84 | 2550 |

| Nickel Binder grades | ||||

| Ọkwa | Ihe nchikota (Wt%) | Njupụta (g/cm3) | Isi ike (HRA) | TRS (>=N/mm²) |

| YN6 | 6 | 14.7 | 89.5 | 1460 |

| YN6X | 6 | 14.8 | 90.5 | 1400 |

| YN6A | 6 | 14.8 | 91 | 1480 |

| YN8 | 8 | 14.6 | 88.5 | 1710 |