Ngwaahịa

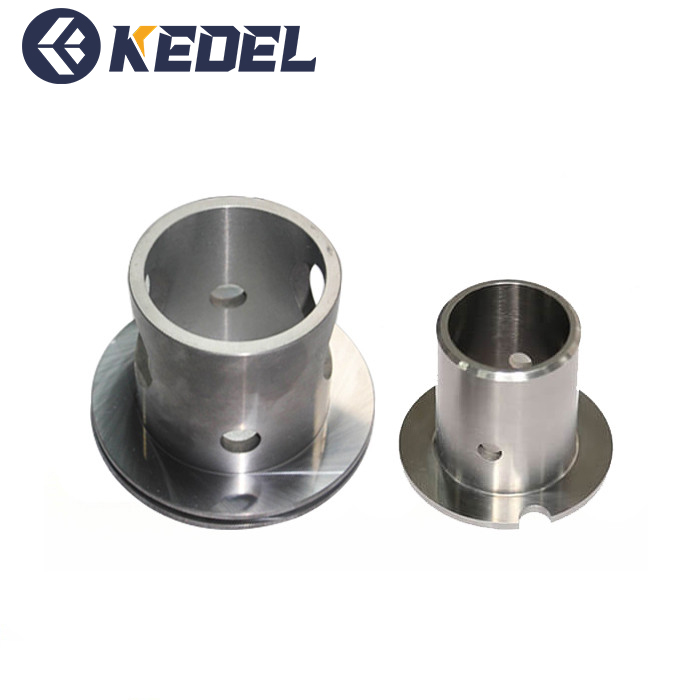

Ahaziri Tungsten carbide Bushing Shaft Sleeve

Okwu Mmalite ngwaahịa

Ngwa Tungsten carbide bush dị obosara, nke bụ ngwaọrụ iji kpuchido klaasị nke akụrụngwa. Ọ bụ na ọrụ n'ezie na ọrụ na ebumnuche nke gburugburu ngwa ya nwere mmekọrịta dị ukwuu. Ngwa Valve, bushings na-etinye n'ime ọnyà valvụ stem cap, iji belata nkwụsị nke valve, iji mechie; ngwa ngwa na-ebu ibu, iji ohia iji belata iyi n'etiti ihe na-ebu na oche oche, zere ọdịiche dị n'etiti oghere na oghere na-abawanye na ihe ndị ọzọ. Tungsten carbide ohia mmepụta na nhazi nke elu-ike, nwere ike idi ogologo ibu ibu, na elu kemịkalụ kwụsie ike, alkali, mmanya, ether, hydrocarbons, acid, mmanụ, detergent, mmiri (mmiri mmiri), na-enweghị isi , na-adịghị egbu egbu, keenweghiuto, na-abụghị nchara e ji mara, ya n'ọtụtụ ebe na-eji petrochemical ụlọ ọrụ maka Submerged Mmanụ mgbapụta, Pumprimp.

Njirimara ngwaahịa

1. Tungsten Carbide Bearing Bushings nwere ihe odide nke nguzogide dị elu, nkwụsị nke corrosion dị elu na ezigbo mkpakọ.

2. A na-ejikarị ya eme ihe na ụlọ ọrụ petrochemical na ụlọ ọrụ ndị ọzọ na-akpọ maka ihe dị elu nke bushings na-ebu ma ọ bụ ogwe aka.

3. Tungsten carbide BEARING bụ ihe bụ isi n'etiti ihe ndị na-ese okwu. A na-ejikarị ha eme ihe dị ka ihe ndị bụ isi maka akara. A na-anabatakwa bushes ndị ahụ na ụlọ ọrụ petrochemical n'ihi ọmarịcha arụmọrụ ya dị ka ike eyi, mgbochi corrosion wdg.

Usoro mmepụta

Egwe ọka--oke dị ka achọrọ --Egweri mmiri mmiri--Akọrọ--Granulation--pịa--Sinter--nyocha--Ngwugwu

Ngwaahịa ndị emetụtara

Tungsten Carbide Bushings

Uwe Carbide maka mgbapụta centrifugal

Ntuziaka Drill Tungsten

Carbide Axle Shaft Sleeves

Ihe nkwụnye carbide

bọọlụ Carbide Valve.

Tungsten Carbide Valve oche na ị ga

Akụkụ Tungsten Carbide mmanụ na gas na-eyi akụkụ na akụrụngwa

Tungsten Carbide nozzles

Ngwa mgbapụta Tungsten Carbide dị elu

Tungsten Carbide maka ihe mgbochi na-efe efe

Ngwa mgbapụta Centrifugal

Centrifugal Carbide Yiri Taịlị

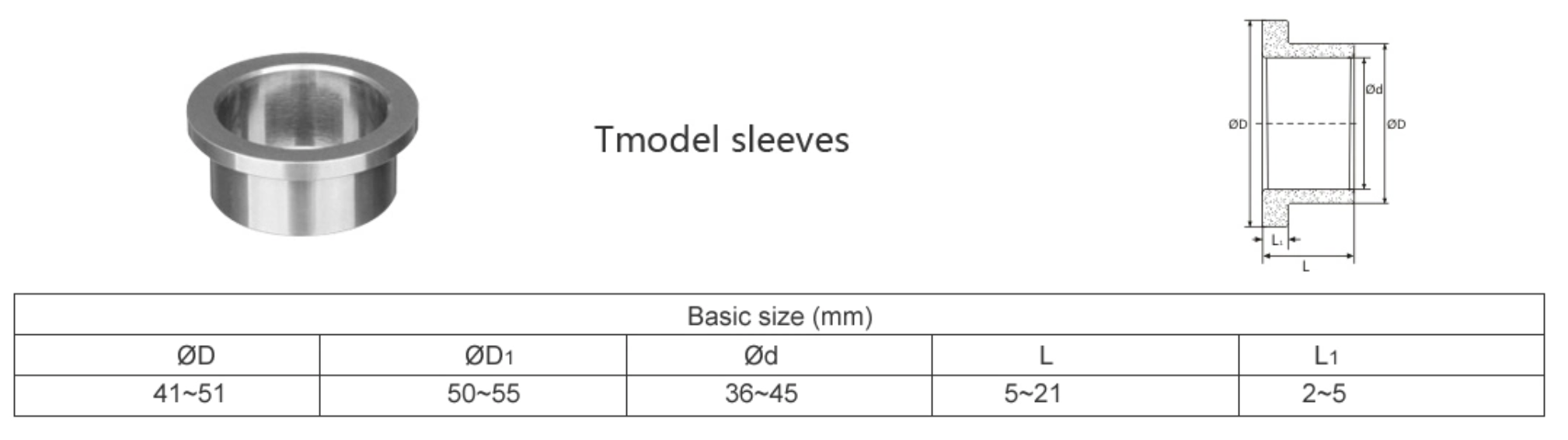

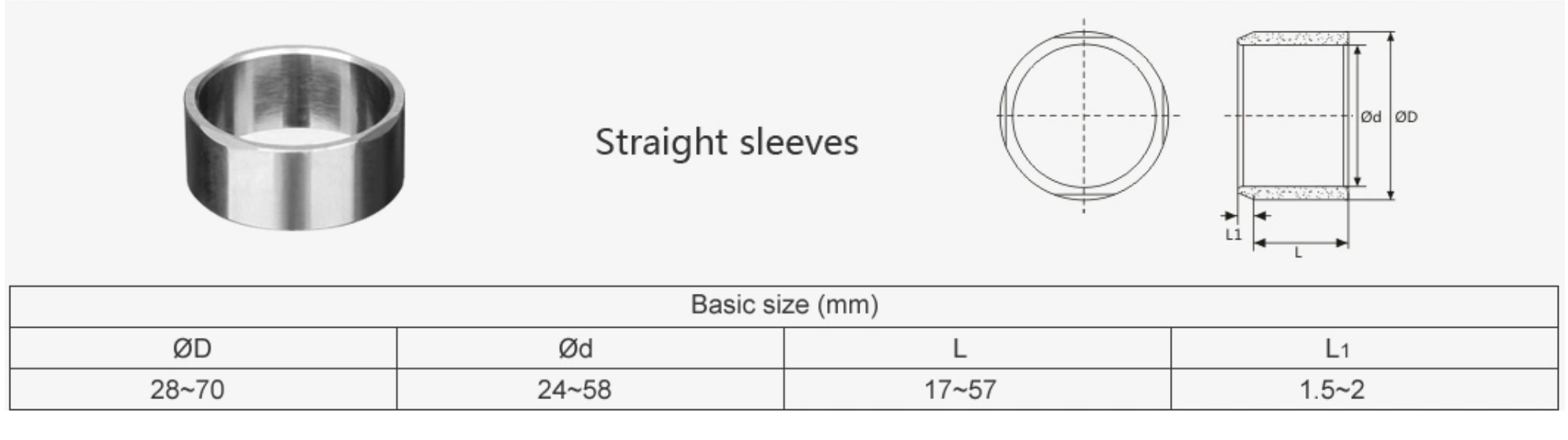

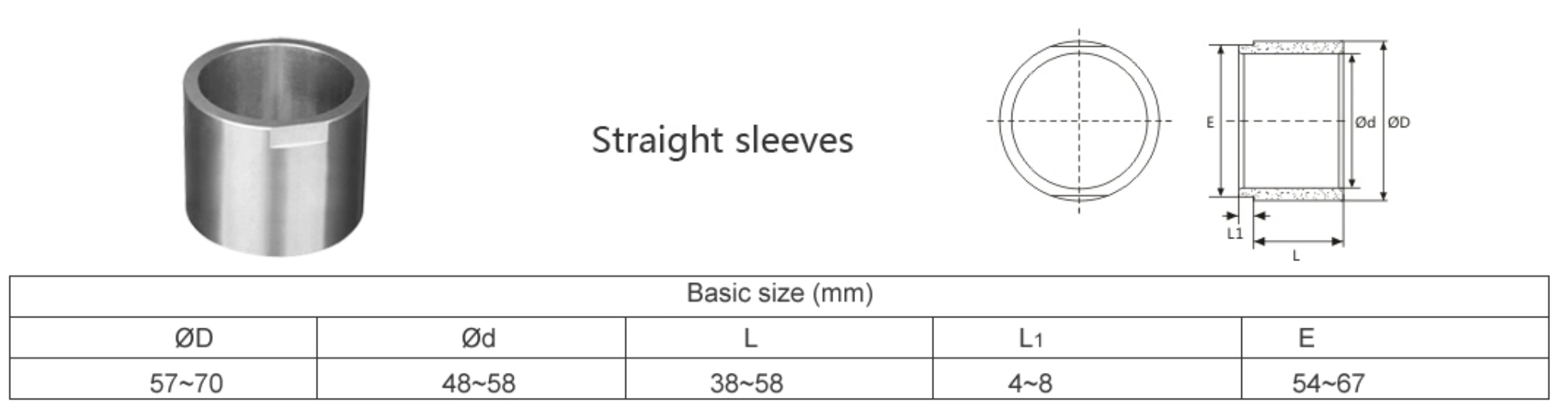

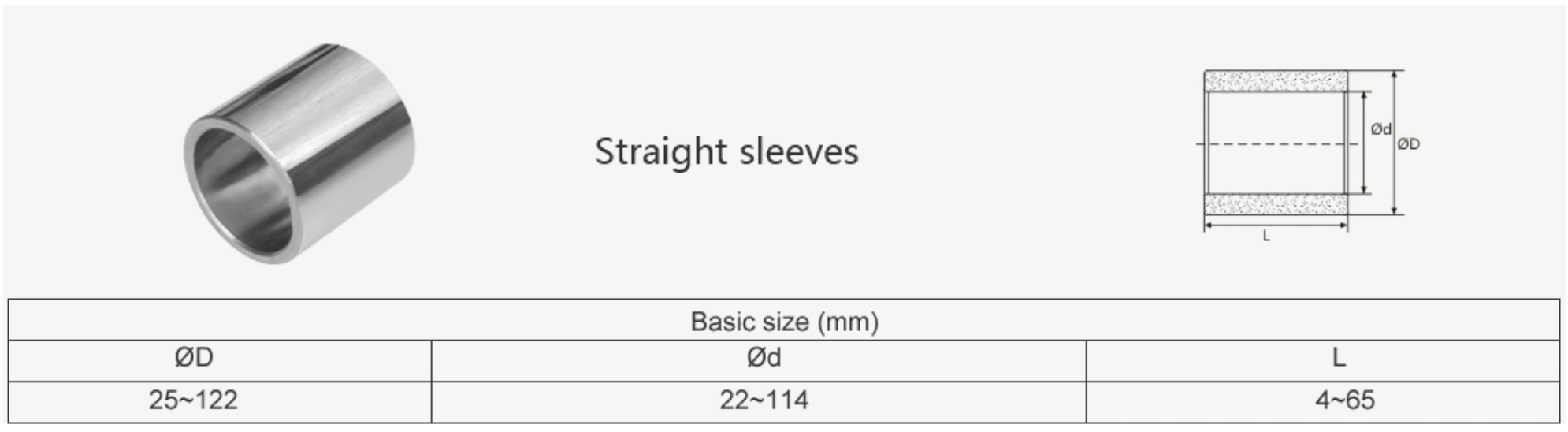

Eserese nha ngwaahịa

Tebụl ihe

| Ọkwa | ISO | Nkọwapụta | Ngwa nke tungsten carbide | ||

| Njupụta | TRS | Isi ike | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Tozuru oke maka iji igwe nkedo oyi, ihe nkedo alloy, igwe nrụgharị na nchara alloy. Tozuru oke maka nhazi igwe nkedo nkịtị. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Kwesịrị ekwesị maka ịmecha machining na ọkara-mechara maka nkedo ígwè, ígwè na-abụghị ígwè, alloy na unalloyed ihe. Tozuru oke maka ịse waya maka igwe na igwe anaghị agba nchara, igwe eletrik maka ojiji geology na igwe igwe wdg. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Ndị ruru eru maka ịrụ ọrụ siri ike nke ígwè nkedo, ígwè na-abụghị ígwè, ihe ndị na-abụghị ígwè, ịbịaru ígwè, ígwè na-adịghị emepụta ihe na ọkpọkọ, ihe dị iche iche maka iji geology mee ihe, ngwá ọrụ maka imepụta igwe na iyi akụkụ. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Tozuru oke maka ịrụ ọrụ siri ike dị ala, igwe igwe titanium alloy na alloy refractory, ọkachasị maka ngwa mbelata na prick silk. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Ndị ruru eru maka ịkpụzi ihe ndị ahụ maka egwu nkume dị arọ: ibe n'ibe ndị a na-apụ apụ a na-eji eme ihe maka igwu mmiri miri emi, rock drill trolley wdg. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Tozuru oke maka mkpọpu okwute siri ike, ogwe nchara nwere oke mkpakọ dị elu, ịse ọkpọkọ, akụrụngwa ịkụ ọkpọ, isi kabinet nke ntụ ntụ metallurgy akpaaka wdg. |

| YG20 | 13.4-14.8 | 2480 | ≥83.5 | Tozuru oke maka ime ọnwụ na mmetụta dị ala dị ka akụkụ ntụmadị, shells batrị, obere skru caps wdg. | |

| YG25 | 13.4-14.8 | 2480 | ≥82.5 | Tozuru oke maka imepụta isi oyi, stampụ oyi na ịpị oyi na-eji maka imepụta akụkụ ọkọlọtọ, bearings wdg. | |