Ngwaahịa

Ihe dị elu Tungsten Carbide polished Rods Round Bar

Okwu Mmalite ngwaahịa

A na-ejikarị mkpanaka carbide eme ihe maka ihe ọkụkụ, ndị na-egbutu ihe na-egwe nri na winches. Enwere ike iji ya maka ịkpụ, stampụ na ngwaọrụ nha. A na-eji ya na akwụkwọ, nkwakọ ngwaahịa, mbipụta, ụlọ ọrụ nhazi ígwè na-abụghị nke ígwè. Tụkwasị na nke a, a na-ejikarị ya eme ihe na-eji ígwè ígwè dị elu na-agba ọsọ, ndị na-egwe ọka carbide, ndị na-egbu osisi carbide, ngwá ọrụ NAS, ndị na-egbu ụgbọ elu, cemented carbide ibe n'ibe, egwe ọka cutter isi ibe n'ibe, elu na-agba ígwè, taperd-egwe ọka cutters, metric egwe ọka cutters, micro ọgwụgwụ egwe ọka cutters, hinge pilot, ngwá electronic.carbide rotary file, cemented carbide tool, wdg.

Nkọwa ngwaahịa

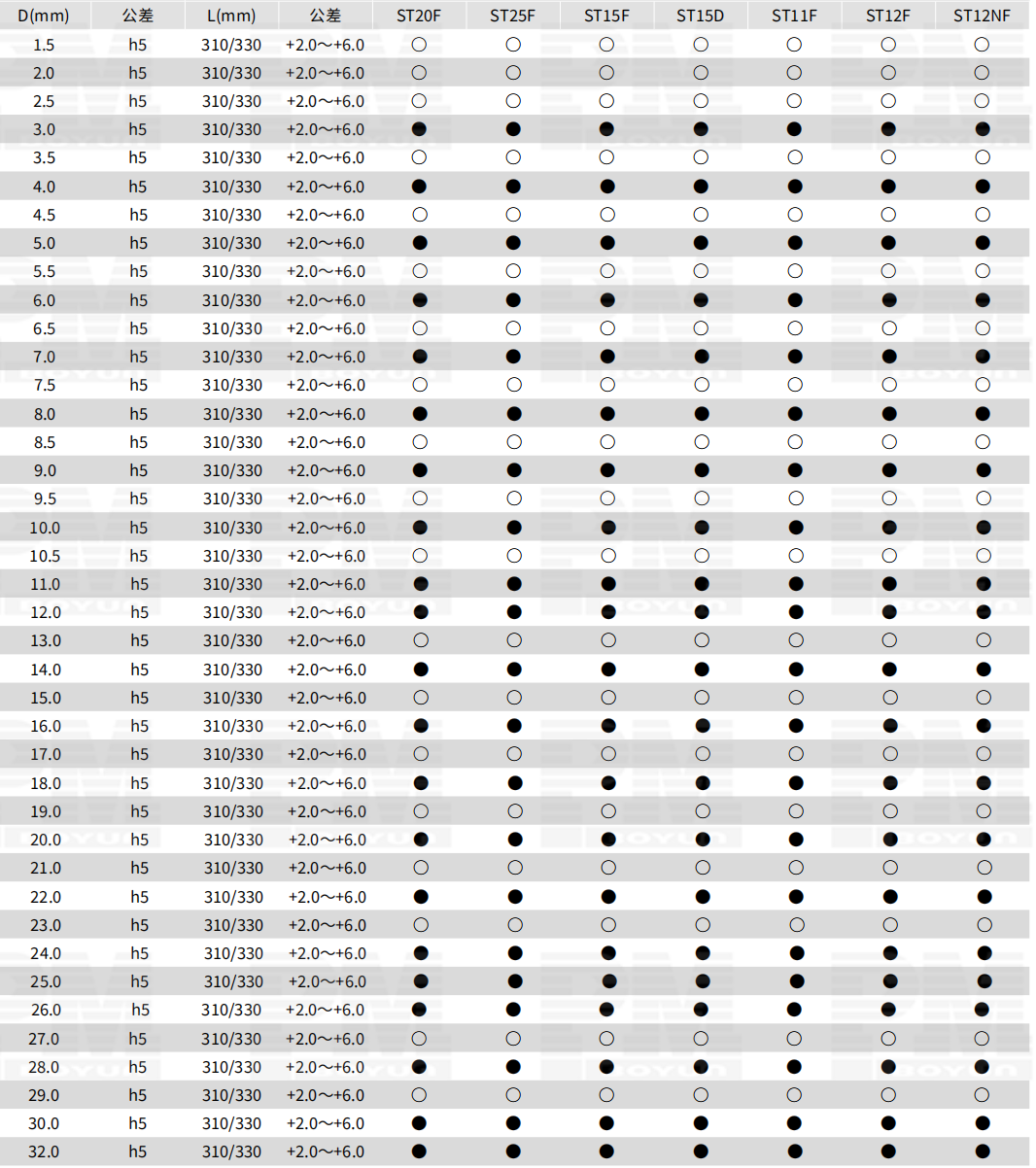

Nha atụnyere aka

Chart ọkwa ihe

| Mmalite ọkwa ọkwa na mkpanaka Carbide | |||||||

| Ọkwa | Co% | Nha ọka WC | HRA | HV | Njupụta (g/cm³) | Ike na-ehulata (MPa) | Njiji siri ike (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | nke kacha mma | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Ọ dị mma | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | nke kacha mma | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | nke kacha mma | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | nke kacha mma | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | nke kacha mma | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | nke kacha mma | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Dee ozi gị ebe a ziga anyị ya